- CN

- EN

#CASES ·2025-09-18

VINAC Supply Chain Management:

Client Background

A leading Saudi Arabian food processing company sought to modernize its production line by integrating advanced conveyor belt systems. The client aimed to enhance operational efficiency, reduce manual labor risks, and comply with stringent hygiene standards for halal-certified food production.

Challenges Identified

Inefficient Material Handling: Manual transfer of ingredients caused delays and product contamination risks.

High Maintenance Costs: Aging conveyor systems required frequent repairs, disrupting production cycles.

Scalability Limitations: Existing infrastructure struggled to accommodate seasonal demand surges.

VINAC’s Tailored Solution

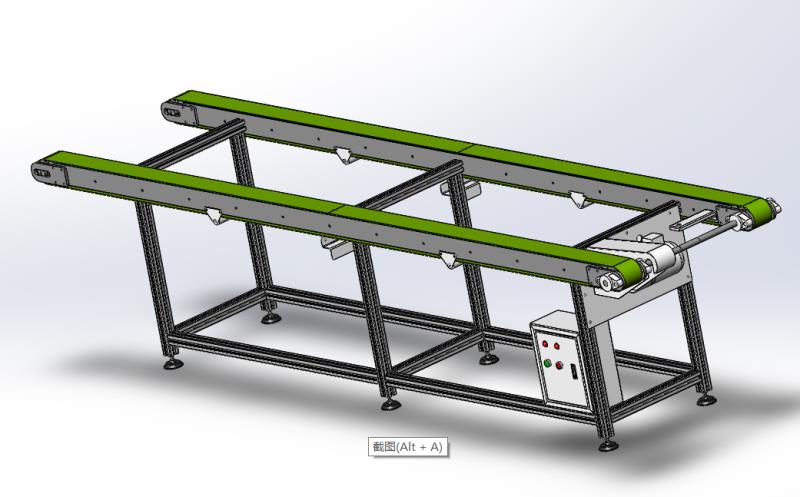

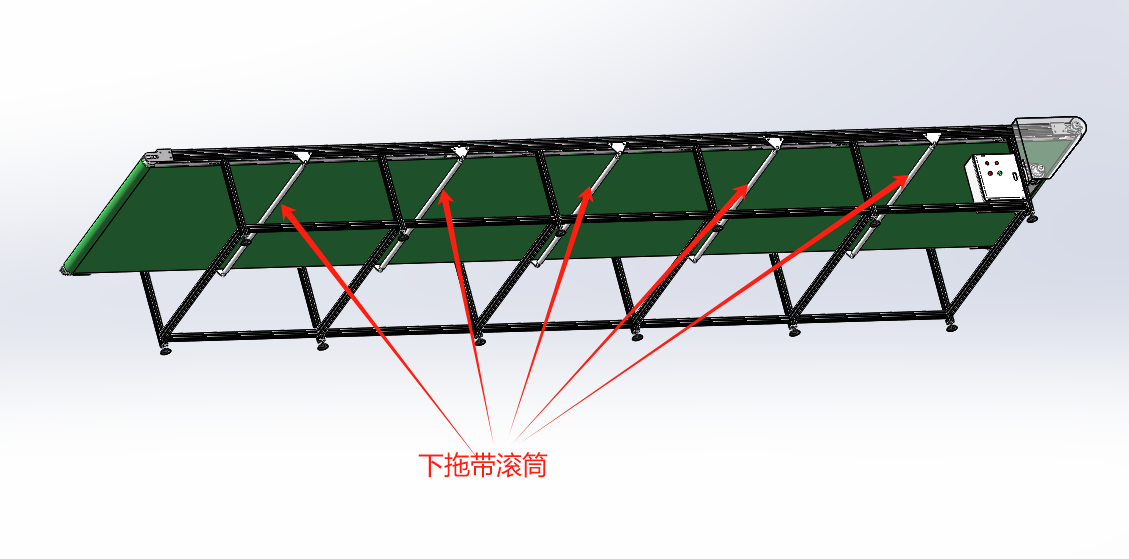

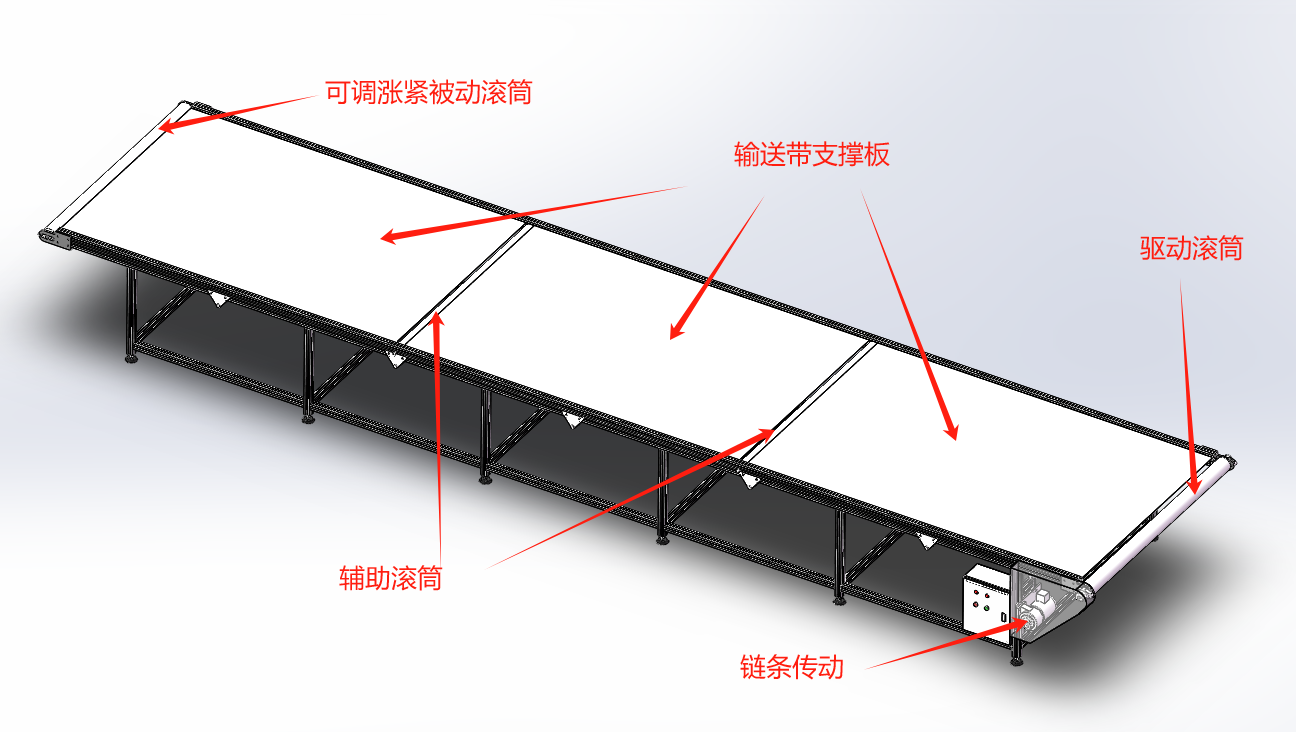

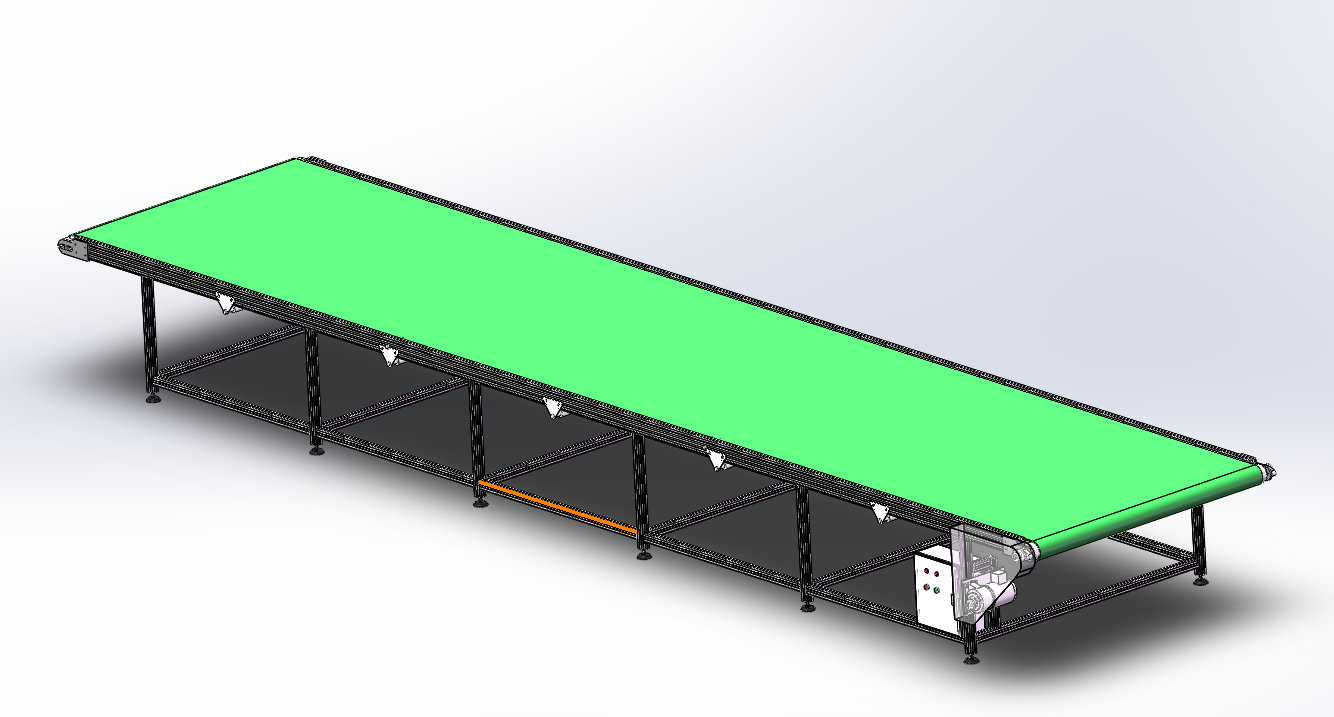

VINAC’s team conducted a comprehensive analysis of the client’s operations and proposed a customized modular plastic conveyor belt system, leveraging insights from industry best practices and regional logistics networks

Key features included:

High-Durability Materials: Corrosion-resistant polyurethane (PU) belts designed for high-temperature environments, aligning with Saudi’s harsh climatic conditions.

Hygienic Design: Smooth, non-porous surfaces to prevent bacterial buildup, critical for halal compliance.

Modular Flexibility: Interlocking panels allowed easy reconfiguration to adapt to varying production line layouts.

Implementation Process

On-Site Assembly: A dedicated team installed the system, integrating IoT sensors for real-time monitoring of belt tension and alignment, minimizing downtime.

Client Benefits

30% Efficiency Gain: Automated material flow reduced manual handling by 40%, enabling 24/7 production cycles.

Cost Savings: Predictive maintenance alerts cut repair expenses by 25%, while energy-efficient motors lowered operational costs by 15%.

Enhanced Compliance: Hygienic design eliminated contamination risks, supporting the client’s expansion into European markets requiring ISO 22000 certification.

Scalability: Modular components allowed the client to add new production lines within 48 hours during peak seasons.

Long-Term Partnership

VINAC provided ongoing support through after sales service center, offering spare parts delivery and technical troubleshooting. The client achieved a 98% on-time delivery rate within six months, positioning it as a key supplier for Middle Eastern retailers.

Conclusion

By combining advanced engineering with localized logistics expertise, VINAC empowered its Saudi client to overcome operational bottlenecks and capitalize on regional growth opportunities. This case underscores the value of tailored supply chain solutions in driving industrial modernization.

2023-01-09

2023-01-09

2023-01-09